Nano to Micro/Macro

Micro-fabrication View all

UVL Ultra Violet Lithography

Ultraviolet lithography also known as optical or photolithography is the most commonly used patterning technique in microfabrication. A photosensitive material (photoresist) is spin-coated onto the substrate to be patterned. The photoresist is illuminated with UV light through a photomask which contains the relevant geometric patterns.

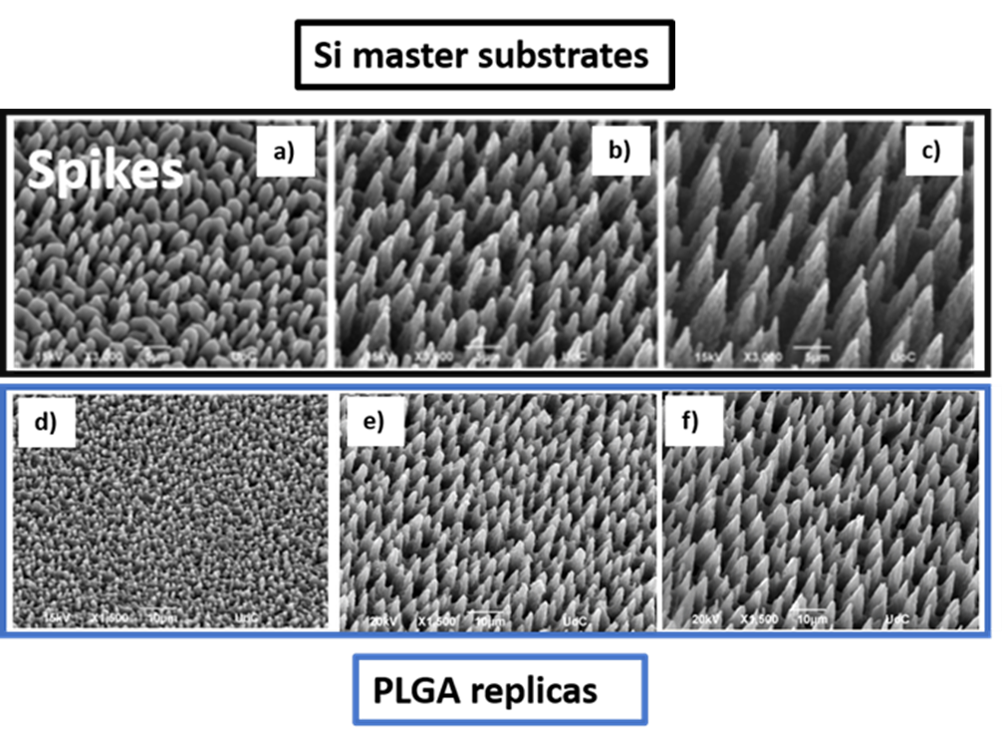

UV-SL UV-Soft lithography

Soft Lithography has been successfully used to transfer well-defined micro sized patterns from rigid materials to surfaces of soft materials and biomaterials eg natural or synthetic polymers, allowing the replication of high fidelity microenvironments at low cost and with great repeatability.

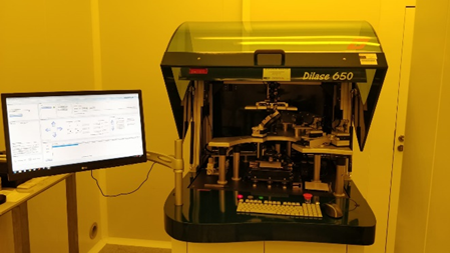

DWL Direct write lithography

Direct Writing lithography (DWL) is a Maskless lithography technique in which the pattern is transferred directly onto the surface of the wafer without the need of a photomask. A direct laser writer, guided by a control computer, “writes” the patterns that conform one layout level directly onto the resist-covered substrates.

I&GLS I & g-line steppers

Geometric patterns in a photo-mask are transferred to a substrate. Mask aligners project in a single UV shot the full wafer design. Steppers project a single chip onto the substrate in a step and repeat sequence. Resolutions (0.5um) and better local alignment with previous patterns are achieved. Max chip size 1.5-2.2 cm. Full wafers only.

II Ion implantation

It is the kinetic insertion of electromagnetically accelerated ions into substrates to change the physical, chemical, or electrical properties of the sample. It is one of the ways how extra dopants are introduced in silicon substrates. Different elements such as B, P, As, Si, N, H, Ar, Ge, Mg, Al, Cl can be implanted. Small pieces can be processed.

SOTP Silicon oxidation and thermal processes

Processes involving exposure of samples to oxidizing or inert ambient at high temperature (300- 1150C). Tubular diffusion furnaces are used for the growth of an SiO2 layer on silicon (as a dielectric or etching/implant hard mask), densification annealing of other layers, metal sintering processes or thermal activation or diffusion of impurities.

Standard depos. Standard chemical and physical deposition cleanroom/lab processes

A set of classical microelectronic processes for deposition, of ancillary materials that are co-adjuvant to the obtention in the micro or nano domain of the functional materials that are the object of the Growth and Synthesis installation. It includes LPCVD and PECVD layers deposition or deposition of metal layers by PVD.

Standard etching Standard dry/wet patterning cleanroom/lab processes

A set of classical microelectronic processes for pattern transfer through etching of thin films than are co-adjuvant to the functional materials of a given sytem under study in the micro or nano domain. It includes wet and dry etching of all those ancillary dielecric or conducting materials.

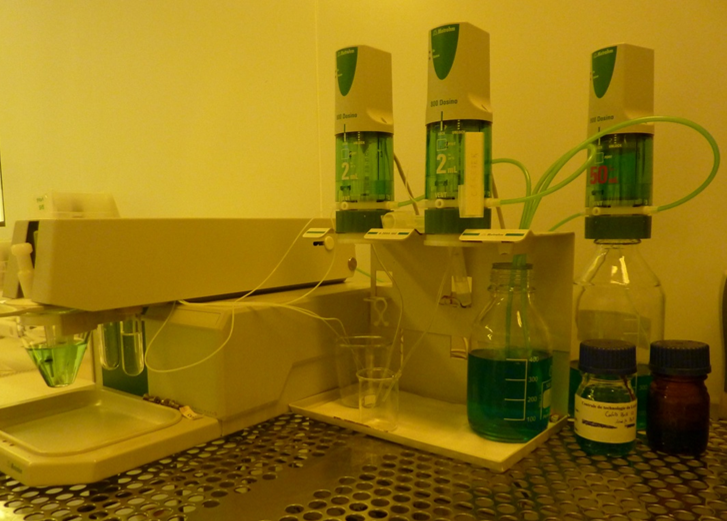

ECD Electrochemical deposition

A metal coating to a metallic or another conducting surface can be applied by means of an electrochemical process. A current is passed from an anode to a cathode through an electrolyte causing the dissociated metal ions to gain electrons and oxidize on the surface of the cathode (surface to be coated), thereby forming a metallic coating.

CD&P Chip dicing & packaging

When components must be tested or used singularly, it provides the device with a mechanical body, environment protection, thermal heat sinking and electrical connection to the real world. It encompasses dicing individual dies with automatic diamond saws and chip-to-package wire bonding (wedge, bond and ribbon).

PSN Plasma Surface Nanostructuring

Plasma processing technique that allows for simultaneous chemical AND topographical modification of polymeric surfaces producing micro and nanotexturing variable in height and density. This nanoroughness in combination with chemical modification may lead to superhydrophilic or superhydrophobic surfaces.

thick films and coatings production View all

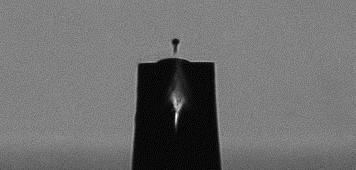

Ink-jet Ink-jet

Inkjet technology uses thermal or piezoelectric nozzle to jet ink drop on demand onto a given substrate for thin film deposition and patterning simultaneously.

SALbL Spray-assisted layer by layer

Spray Assisted Layer-by-Layer assembling coating is a chemical assembling process based on chemical and/or electrostatic interactions which establish between the materials building blocks consisting of polymers and nanoparticles, very useful to realize multifunctional and smart coatings.

SS&RP Screen-stencil & roller printer

In the advanced ceramics field, screen printing represents the main technique for the industrial production of thick films (layers with a thickness between 100 and 1 µm) for microelectronic applications (circuits, conductors, resistors, etc.) due to its simplicity, the high printing definition and the low-cost.

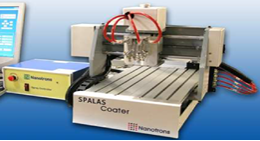

ARC Automated road coater

Rod coater is a simple device which is currently used to develop and scale polymeric coatings formulations to roll-to-roll industrial applications. The multifunctional and smart polymeric coating formulations made of polymers, nanoparticles and suitable additives, are deposited on different by means of a rod bar able to deposit different thickness.

Tape casting Tape casting

Tape casting is a simple and versatile shaping technique that allows the production of planar sheet of ceramic or other materials with thickness ranging between 30 µm to 1.5 mm.

3D shaping View all

LSIVP Laser surface and in-volume Patterning

Laser patterning is a technique for the controlled patterning of materials at micro- and nano-scales. It offers the ability to directly write patterns on the surface and complex 3D channels into the bulk of solid materials, also biomaterials. Applications can range from microfluidic systems and sensors to tissue engineering scaffolds.

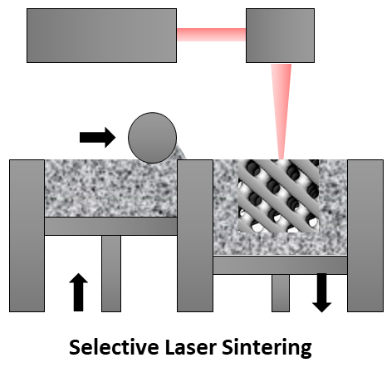

SLS SLS selective laser sintering

Selective laser sintering (SLS) is a solid freeform fabrication technique. SLS produces physical models through a selective solidification of thermoplastic polymer and/or composites. The SLS technique uses a CO2 or Nd:YAG laser beam for scanning successive layers of powdered materials to create a 3D object.

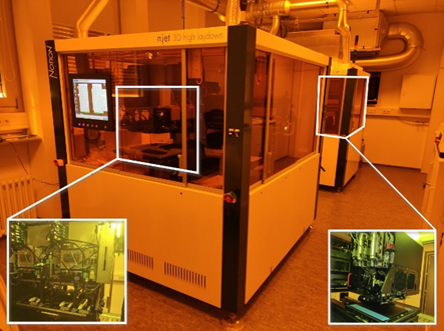

3D MP 3D Micro Printing (MP)

3D Microprinting by fused filament fabrication or 3D inkjet printing shows enormous potential for the realization of 3D structures with microfeatures. Recent developments have enabled processing of diverse materials, from pure polymers to highly filled composites for creating functionality enhanced 3D multi-material parts with intricate features.

FDM FDM fused deposition modeling

FDM (Fused deposition Modeling) is a unique additive manufacturing technique where printers use a thermoplastic type of filament heated to reach its melting temperature, followed by layer by layer extrusion, thereby leading to the fabrication of a 3 dimensional structure.

Slip casting Slip casting

Slip casting is a common shaping technique that allows the production of complex ceramic shapes using specific moulds.

Synthesis of dispersed-phases View all

DNP Dispersion of nanoparticles

The dispersion of nanoparticles in different fluids is a fundamental tool for obtaining colloids, nanofluids, emulsions, which have various applications ranging from microfluidics, to life sciences, energy efficiency, etc.

FF Formulation of fluids (inks, pastes, suspensions, colloids,etc.)

Several of the processes dedicated to the production of 2D/3D samples requires the formulation of a suitable suspension of the particles in a specific medium. The installation is devoted to formulate inks, suspensions, colloids, etc. specially engineering for a specific shaping process.

EoC Engineering of colloids

The engineering of colloids allows to prepare dispersions with the required characteristics needed for specific applications of higly engineered materials.

2D/3D bio-printing View all

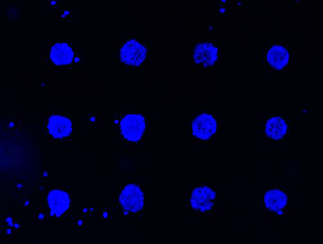

MS Micro-spotter (protein spotting on surfaces)

Non-contact printing is a technology based on a piezoelectric system, which consists in depositing drops of very low volume of samples (100 pL) without touching the surface, avoiding the risks of surface contamination. This technique is very flexible both in term of sample and of surface to modify.

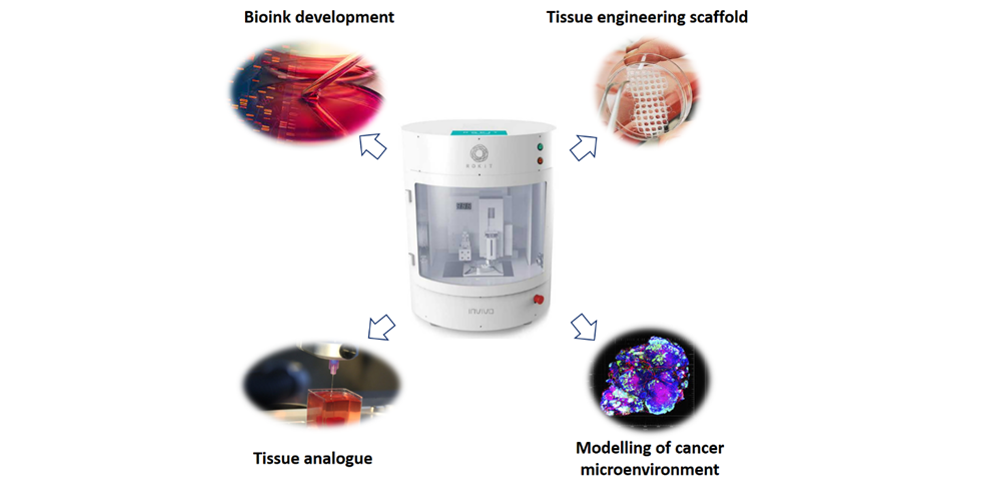

3DBP 3D bio-printing (temporarily unavailable)

Bioprinting, a computer-assisted technology, is able to assemble tissues through “layer-by-layer precise positioning of biological materials, biochemical and living cells, with spatial control of the placement of functional components. Bioprinting aims to produce engineered tissue or organ in a mechanized, organized, and optimized manner.

in vitro assays and cell analysis View all

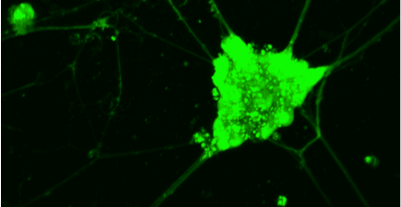

LCI Live cell imaging

The “Live Cell Imaging” facility is equipped with advanced imaging microscopy techniques (based on two- or multi- photon excitation), which are appropriate for the all-optical minimally invasive, high-resolution (<500nm), deep (>500μm) monitoring of living cells and tissues for long periods of time.

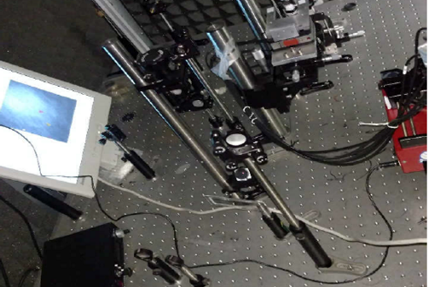

DH Digital holography

Digital Holography Microscopy (DHM) has become a powerful and versatile tool for life sciences, biophysics and biotechnology. This is a custom setup, based on an inverted optical microscope, combining brightfield illumination and digital holography dedicated mainly to live cells imaging.

MHCACC Microscope for high content analysis of cell culture (high throughput cell analysis)

The instrument is a super-fast and sensitive fluorescence wide-field cell imaging system, fine-tuned to the needs for high-content screening (HCS) and high-content analysis (HCA).

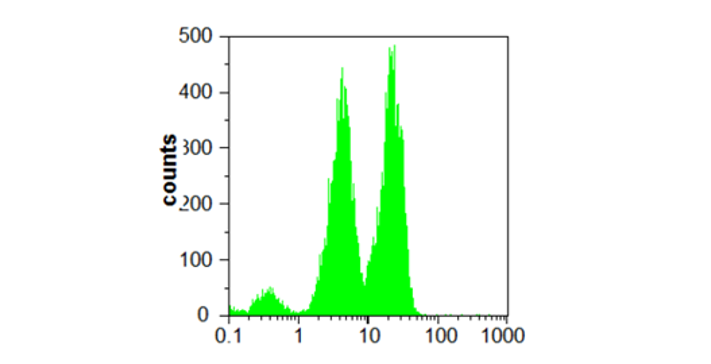

FC Flow cytometry (cell sorting)

The benchtop flow cytometer is highly versatile for most applications in cell and particle analysis as well as absolute counting.

INA In Vitro Assays

In vitro assays on cell cultures allow the study of biological functions and phenomena: each type of assay corresponds to a biological function or mechanism. These assays are used to assess the safety of advanced materials and in particular nanomaterials.

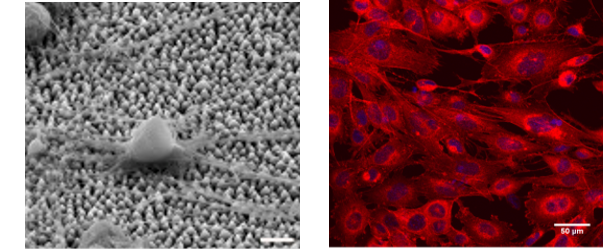

CCF Cell culture facilities

The Cell Culture Facility provides the necessary equipment (basic cell culture, sample preparation, functional assays and imaging equipment) for the study of the effect of biomaterials on specific cell behavior and function and cellular responses, such as cell survival, adhesion, morphology, proliferation, growth, migration and differentiation.

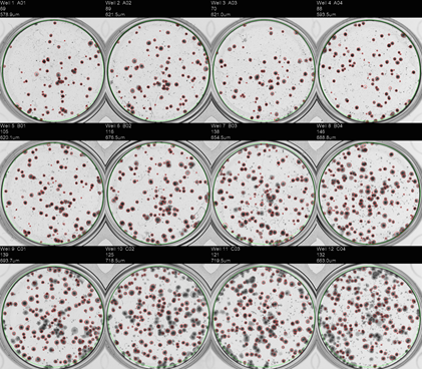

HTS High-Throuput Screening

High-throughput screening (HTS) cell-based assays are able to evaluate compound effects on cellular models through absorbance, fluorescence, and luminescence measurements. HTS has been further facilitated by automated liquid handling systems, allowing the rapid screening of large libraries of compounds.

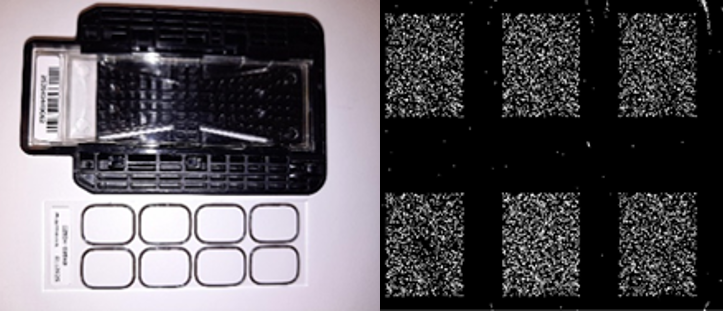

3DC 3D and organotypic cultures cell assay systems

3-D culture systems aim to resemble the architecture and cellular interactions found in tissues. Culturing cells in matrices or scaffolds allows a deeper understanding of tissue development and regeneration, as well as the effects of compounds on biological systems. These culture models enhanced our understanding of cellular processes and diseases.

Biomolecules and biomaterials analysis View all

OM Optical Manipulation

Optical tweezers use radiation pressure of a laser focused by an optical microscope to handle micro-objects and to apply pN forces and can be joined with optical spectro-microscopies. At present we offer multiple trapping, manipulation, force measurements, laser microsurgery, Raman spectroscopy, phase contrast imaging, TIRF and FRET are operative.

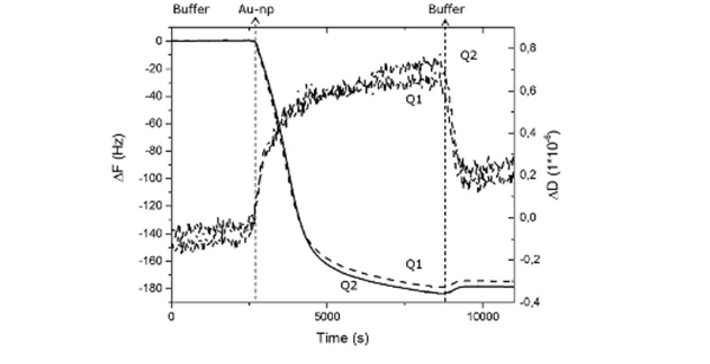

QCMB Quartz crystal microbalance biosensor(Biomolecular real-time detection)

QCM-D is a real-time surface sensitive technology that detect mass changes at the sensor surface with nanoscale resolution. In practice, this instrument is a balance for very small masses and the molecule-surface interactions are detected as changes in mass. In addition to the changes in mass QCM-D also captures changes in energy loss.

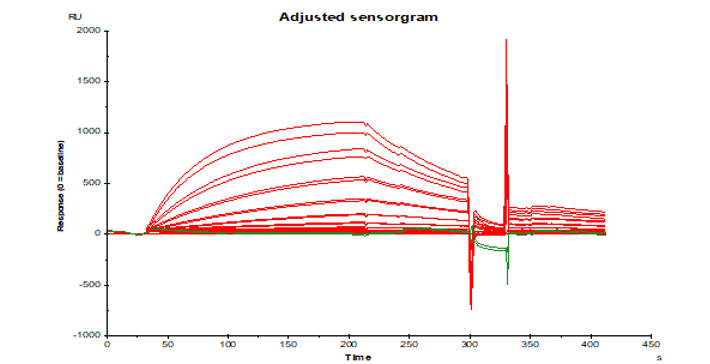

SPRB Surface Plasmon Resonance Biosensor (Biomolecular real-time detection)

Surface plasmon resonance instruments enable to measure in real time the biomolecules binding onto the sensing surface by monitoring the induced plasmonic resonance peak shift at the gold-liquid interface. This technique allows real-time detection and monitoring of biomolecular binding events.

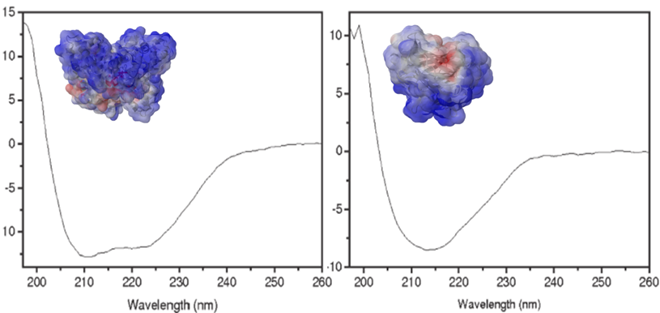

CD Circular dichroism (protein structure analysis)

Circular dichroism (CD) is a spectroscopic technique that allows the rapid determination of the secondary structure and folding properties of purified proteins. The most widely used applications of protein CD are to determine whether an expressed, purified protein is folded and its thermal stability.

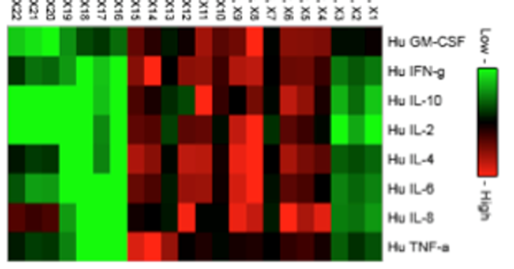

Elisa-PR Elisa (enzyme-linked immunosorbent assay) plate reader / Multimode plate reader

The instrument uses the Luminex technology based on magnetic beads for multiplex immunoassays.

DNAMS DNA Microarray scanner (Absorbance Fluorescence Luminescence)

The microarray scanner is a laser-induced fluorescence scanner designed to read microarrays printed on standard 1 in × 3 in slides. The microarray scanner measures the fluorescence intensity of labelled sample nucleic acid (DNA and RNA) bound to microarrays.

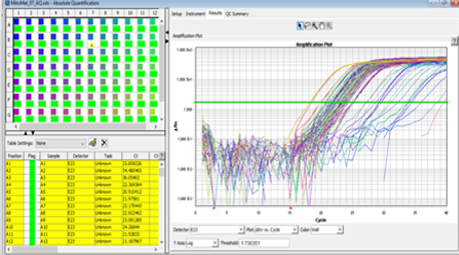

RT PCR Real time Polymerase chain reaction (RT PCR)

Real-time PCR (also called quantitative PCR - qPCR), combines PCR amplification and detection into a single step. This eliminates the need to detect products using gel electrophoresis, and it enables the method to be truly quantitative. With real-time PCR, fluorescent dyes are used to label PCR products during thermal cycling.

Rheology analysis View all

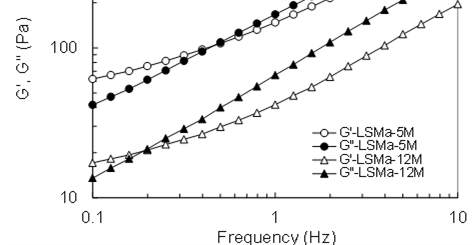

MM Mechanical moduli

This technology allows to investigate the viscoelastic behavior of complex fluids.

Viscosity Viscosity

This technology allows to measure the viscosity of simple and complex fluids and for non-Newtonian fluids to determine its dependency on the flow conditions (shear rate).

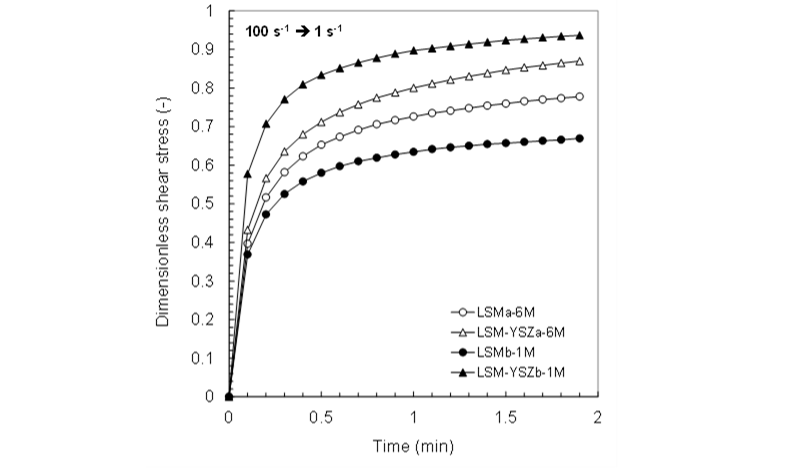

Thixotropy Thixotropy

This technology allows to investigate the thixotropic behavior of complex fluids, i.e., the dependence of viscosity on time after changes in the flow conditions.

Mechanical analysis View all

MP Mechanical properties

The mechanical properties of materials can be investigated with a set of characterization tests that lead to the measure their mechanical resistance.

TMP Thermo-mechanical properties

The mechanical properties of materials can be investigated even at high temperature to understand the change of the mechanical properties at high temperature.

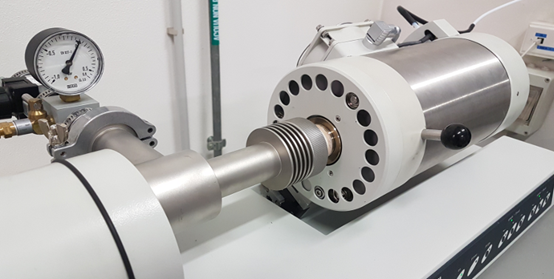

TDA Thermo-dilatometric analysis

Dilatometry is a thermoanalytical technique used to measure the length of samples, under negligible constant load when subjected to a controlled temperature/time program.

Electrical analysis View all

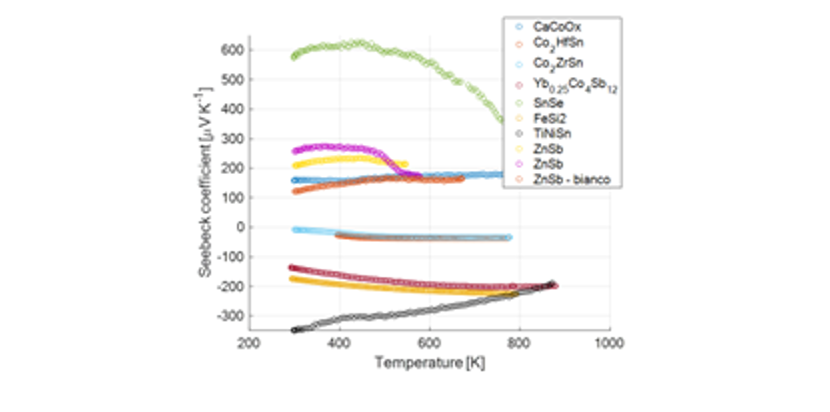

TP Thermoelectric properties (temporarily unavailable)

Functional characterization of thermoelectric materials, including electrical conductivity, Seebeck coefficient and thermal conductivity in the room temperature – 800 °C range. Thermoelectric planar module testing (power output, conversion efficiency) up to 600 °C.

RF-VNAC RF VNA characterization with probe station

A VNA (Vector Network Analyser) is the technique used to characterize the electrical response of any electrical network (a circuit or component) with a given number of ports (inputs/outputs) in terms of their electrical response at alternating signals of a given frequency.

EC Electrochemical characterisation

Cyclovoltammetry, is an analytical method for detecting and characterizing oxidizable and reducible compounds in solution. This method is specially used for additives concentrations analyses in copper electroplating bathes.

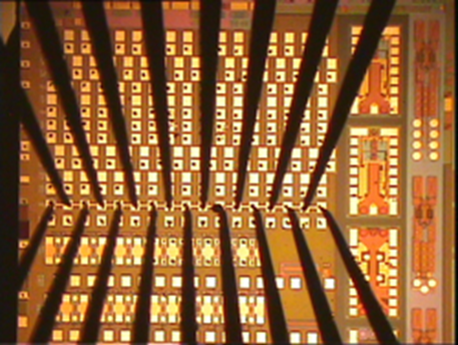

MET Microprobe electrical testing

Microprobe stations allow measuring at chip level and at wafer level (before dies are being cut and used singularly) in combination with equipment for AD/DC measurements, such as a good number of semiconductor parameter analyzers, impedance analyzers, voltage and current sources, capacimeters, and dedicated test structures.

MPET Mercury Probe Electrical Testing

The Mercury Probe is an electrical probing device to make rapid, non-destructive contact to a sample for electrical characterization. Its primary application is semiconductor measurement where otherwise time-consuming metallization or photolithographic processing are required to make contact to a sample.

Thermal analysis View all

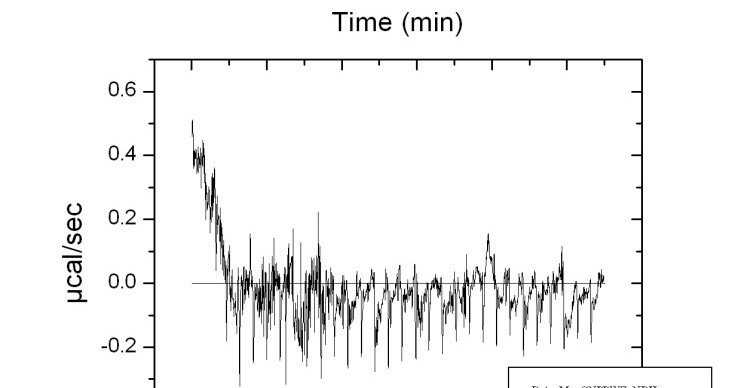

IC Isothermal Calorimetry

Isothermal Titration Calorimetry (ITC) is a technique that measures the heat that is either released or absorbed during a biomolecular binding event, providing information binding affinity and thermodynamics: binding constants (KD), reaction stoichiometry (n), enthalpy (∆H) and entropy (∆S).

TC/D Thermal conductivity/diffusivity

TEMPORARILY UNAVAILABLE

The laser flash method allows to measure materials thermal diffusivity with high accuracy (typically below 3%) and in a wide range of temperatures.

TGA Thermogravimetric Analysis (TGA)

The thermal analyses are the set of techniques in which a physical property of a substance is measured as a function of temperature (or time) while the sample is subjected to a controlled temperature program (heating, cooling, isotherm).

DSC Differential Scanning Calorimetry (DSC)

Differential Scanning Calorimetry (DSC) measures the difference in the amount of heat required to increase the temperature of a sample and reference as a function of temperature and therefore considers its energetic variation.

STG-DSC-DTA Simultaneous TG-DSC-DTA

In the Thermogravimetric Analysis (TGA) the mass of a sample is measured as a function of temperature or time, while the Differential Scanning Calorimetry (DSC) measures the difference in the amount of heat required to increase the temperature of a sample and reference as a function of temperature.

HTM HT-microscopy

The heating microscope allows to “visually” follow what occurs to the specimens subjected to heat treatment. In this way, it is possible to achieve information about: melting of the material (softening temperature, hemisphere temperature and sphere temperature).

Micro-macro simulation methods View all

DEMS Discrete element modelling and simulation

This technique offers the possibility of modelling and simulating particle systems characterised by elastic, elasto-plastic, electrostatic and/or thermal-fluid dynamic interactions. Example application areas include mixing and segregation of materials, pharmaceutical processing, friction, and lubrication.

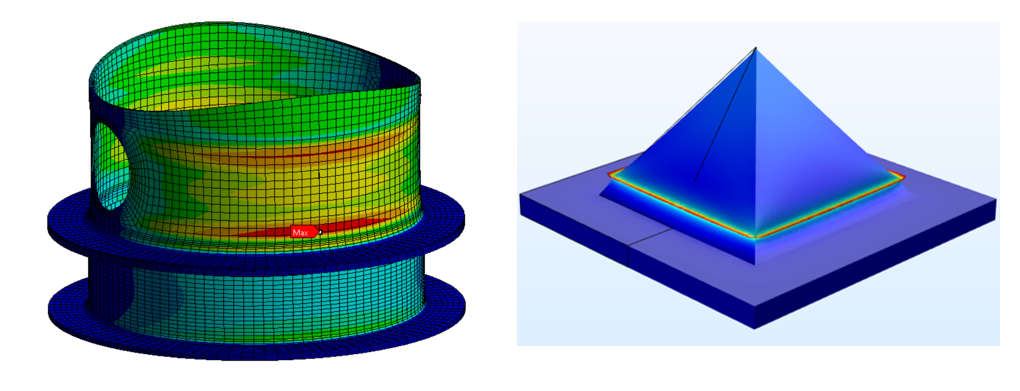

MFES Multiphysical finite element simulation

This technique offers the possibility of modelling and simulating continuous systems, characterised by elastic, elasto-plastic, thermal, electromagnetic and/or fluid-dynamic interactions.