SLS selective laser sintering

Nano to Micro/Macro (3D shaping)

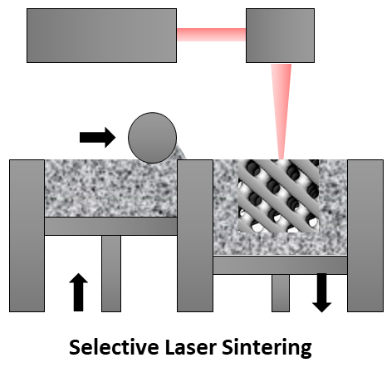

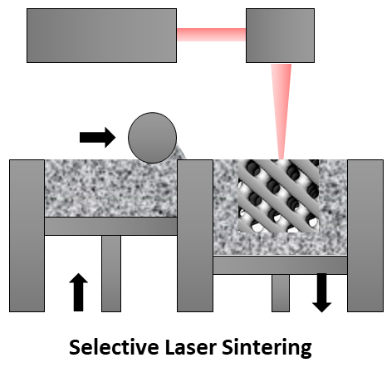

Selective laser sintering is an additive fabrication process that quickly produces models and prototype parts from 3D CAD models, 3D digitizing system-acquired data, CT and MRI scan data. The SLS process fabricates parts by fusing powdered materials typically with a with a CO2 or a Nd:YAG laser. The powdered material is spread by a roller over the work surface and preheated to a temperature slightly lesser than its melting point, and then a laser beam traces the cross-section on the powder surface to heat up the powder to the sintering temperature so that the powder scanned by the laser gets bonded. After completing one layer, the roller spreads another layer of fresh powder over the sintered one and the building process is repeated until the whole part is complete. The manufactured objects are then extracted from the building platform and sanded to get a powder free surface of them.

Free shape objects, objects within objects and articulated objects can be obtained in one forming process. Typically it is not thought as a technique for fabricating electronic or active devices themselves, but auxiliary pieces or holders where the devices may be encased.

The advantage of this technique is easy post processing and no requirement of support structure and the possibility to use variety of thermoplastic powders.

Depending on the specific system, a wide range of materials could be processed including thermoplastic polymers and composites. Typical processed polymers can be: polycarbonate (PC), polyvinyl chloride (PVC), acrylonirile butadine styrene (ABS), polyamides (PA-11 and PA-12/PA2200), thermoplastic polyurethane (TPU), polycarbonate urethane (PCU), polycaprolactone (PCL), etc. Among composite materials, the SLS is capable of processing many polymer/ceramic, polymer/carbon nanotubes and polymer/graphene powder.