3D bio-printing (temporarily unavailable)

Nano to Micro/Macro (2D/3D bio-printing)

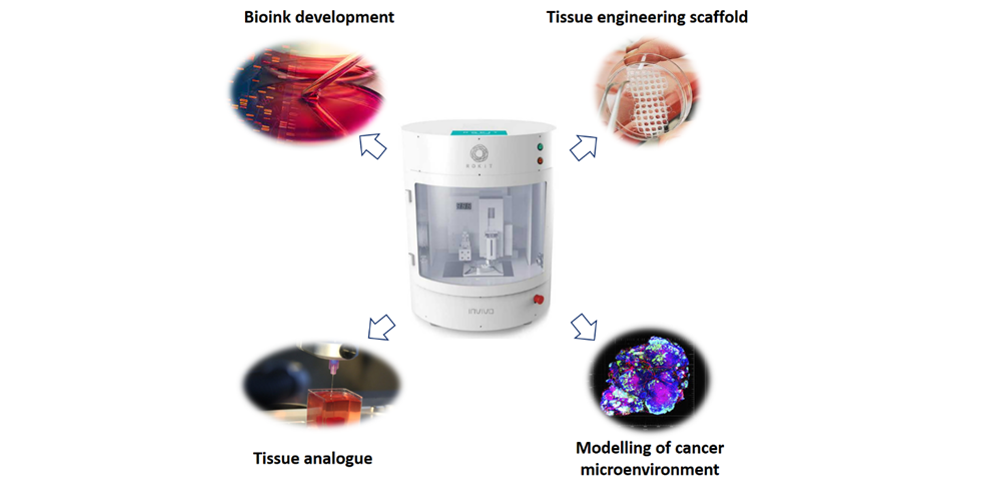

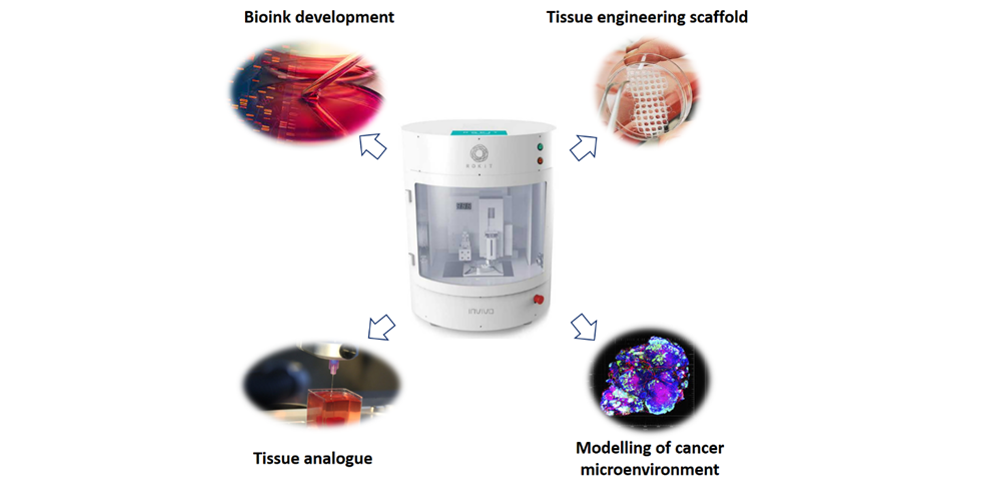

Based on computer-aided motion, extrusion-based 3D bioprinting precisely dispenses living cells and biomaterials layer by layer, generating structures that imitate native human tissues and biological systems. The technology brings key values of automation, biomimetic architecture, and on-demand biomanufacturing. It is widely applicable to the fields of bioengineering and medicine, from in vitro applications in novel product screening, disease modelling, and animal alternative experimentation to in vivo applications in tissue transplantation and regeneration.

Rokit Dr. INVIVO 4D2 is the first clean-chamber bioprinter (HEPA filter, UV lamps for disinfection) pioneering the way for effective, on-demand biofabrication of human tissue models and implants. It is capable of printing freeform cell suspensions, hydrogels, thermoplastic filaments, pastes, and other composite materials, enabling both hard and soft tissue engineering. It is a flexible platform for enhancing complex, precision-based tissue engineering construct. It has been designed with a modular, dual print head system, allowing processing a wide range of thermoplastic polymers and hydrogels. Materials can be deposited using three types of printing technology, including syringe dispenser, filament extruder and hot-melting pneumatic dispenser. The main features of the syringe dispenser are: Nozzle size 100 to 600µm, operating temperature range from -4 to 60°C and printing pressure range is 3-300 kPa (0.3bar). The main feature of filament extruder are: noozle size 100 to 400 µm, operating temperature from room temperature to 250°C. The main feature of the Hot pneumatic dispenser are: noozle size 100 to 600µm, printing max pressure is 980kPa (9.8 bar), operating temperature from room temperature to 350°C.