Unveiling nanoscale chemical inhomogeneity in surface oxide film on tooling alloy by synchrotron X-ray analyses

Modern tooling alloys contain Cr- and V-nitride particles in the alloy matrix. The chemical state of the surface layer, including the passive film and the underlying alloy layer (of nanometer thickness), determines the corrosion resistance, which is crucial for their applications. In this work, we have used synchrotron-based HAXPEEM/HAXPES and µ-XAS measurements with high lateral resolution to gain detailed understanding of the correlation between microstructure and chemical state of the surface layer (i.e. lateral variation in composition of the passive film related to precipitated particles in the microstructure), as well as the effect of tempering heat treatment.

NFFA-Europe has offered a unique opportunity that enabled us to conduct this correlative microscopic study using different world-class techniques and methods.

This work is a joint effort between researchers with diverse expertise at both academic and industrial organizations, including material and corrosion experts, instrument experts, and beam scientists in different countries. HAXPEEM/HAXPES measurement was performed at PETRA III, DESY, in Hamburg, Germany, while µ-XAS measurement was performed at MAX IV in Lund, Sweden.

“The exciting feature of this work was the possibility of identifying the same micron-sized sample areas in different instruments with the help of DESY Nanolabs marker technology*, enabling us to precisely correlate results from HAXPEEM and HAXPES at PETRA with SEM imagery and µ-XAS taken at MAX IV. One always learns something when applying a combination of different methods to the same material, but here the situation was especially challenging due to the inhomogeneous microstructure of the sample”, says Carsten Wiemann who operated the HAXPEEM instrument.

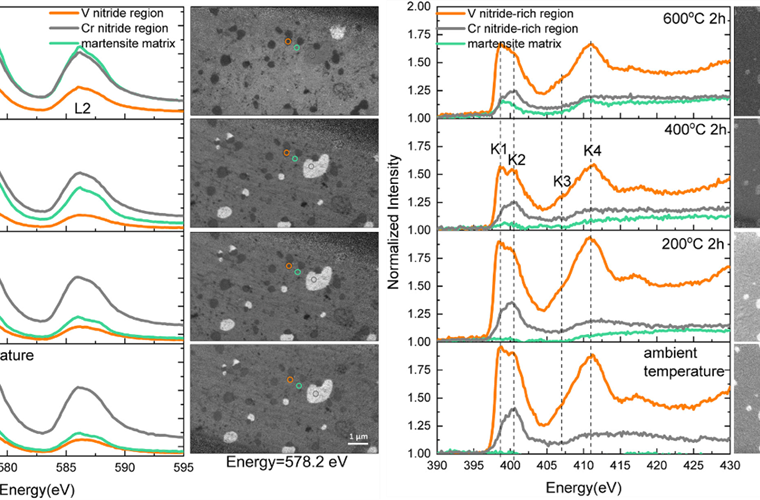

SEM/HAXPEEM images and XPS spectra of CrN and VN particles. Copyright: Xiaoqi Yue.

“This research exemplifies the innovative application of PEEM in unraveling the chemical complexity of surface oxide film formed on metal, advancing corrosion science and material engineering”, says Yuran Niu, the beam scientist at MAX IV who helped the micro-XAS measurement.

Our work has demonstrated the feasibility of revealing nanoscale inhomogeneity in surface layer of advanced alloy with complex microstructure, which is of great importance in material engineering and corrosion science. The groundbreaking new knowledge gained from the measurement will enable optimisation of the alloy design and heat treatment.

“This work has enabled us to understand the nature of the passive film that forms on both the martensitic matrix and on the hard phases. The gained knowledge will play a key role in our future alloy development leading towards a long-lasting material in demanding environmental conditions”, says Krishnan Anantha who is the material and corrosion expert at Uddeholms AB.

SEM/EDS images showing CrN (light gray) and VN (dark gray) particles after austenitization at 1010 °C (a) and 1080 °C (b).

* Nano-object transfer and positioning is a Lithography & Patterning procedure developed in an earlier phase of NFFA by the Consortium researchers, and it is included in the NFFA catalogue for the benefit of the whole community. The ability to locate and mark a given area of measurement and retrace it when moving the sample to another instrument/technique is of paramount importance for drawing valid conclusions from the aggregated data obtained, especially when the sample under test is not spatially homogeneous. Find out more about this technique.

X. Yue, D. Chen, A. Krishnan, I. Lazar, Y. Niu, E. Golias, C. Wiemann, A. Gloskovskii, C. Schlueter, A. Jeromin, T. F. Keller, H. Tong, S. Ejnermark, J. Pan, “Unveiling nano-scale chemical inhomogeneity in surface oxide films formed on V- and N-containing martensite stainless steel by synchrotron X-ray photoelectron emission spectroscopy/microscopy and microscopic X-ray absorption spectroscopy”, J. Mater. Sci. & Tech., 205 (2025) 191. doi.org/10.1016/j.jmst.2024.04.006

Thanks to the support provided by NFFA-Europe, we used the facilities at DESY NanoLab to deposit Pt fiducial markers on the sample surface for regions of interest (ROI) selected for analysis. Additionally, we received extra beamtime to perform time-consuming HAXPEEM measurements. This enabled one-to-one correlation between the analysed area to the microstructure feature of the sample. It also allowed us to locate the same area for measurements using different instruments, facilitating correlative microscopic studies with multiple techniques.

Jinshan Pan is a professor of corrosion science at KTH Royal Institute of Technology, Stockholm, Sweden. He completed M.Sc. in Surface Science & Corrosion Engineering at University of Science & Technology Beijing, China, in 1986, and his PhD in Corrosion Science at KTH, Sweden, in 1996. He became a full professor at KTH in 2010. Prof. Pan’s research is focused on the study of passivity and localized corrosion of advanced alloys as well as novel green corrosion protection strategies by using advanced electrochemical methods and state-of-the-art microscopic and spectroscopic analytical techniques. In recent decade, Pan’s group has made significant effort to utilize world-class synchrotron techniques, in combination with electrochemical technique, for in-situ and operando measurements to gain fundamental understanding of corrosion processes of advanced alloys. Moreover, Pan’s group also performs theoretical modeling including FEM simulation and DFT calculation to study localized corrosion mechanisms. Pan has supervised 14 PhD students and 10 postdoc researchers, and published 200 peer-reviewed articles, cited 10,325 times with an H-index of 55 until January 20, 2025 (google scholar). He has also made a large number of oral presentations at international conferences, and acted as faculty opponent for 12 doctoral defenses at different European countries and grading committee member for 14 doctoral theses in Sweden. Pan has received funding supports for many major research projects from Swedish Research Council, Swedish Foundation for Strategic Research, Sweden’s Innovation Agency, Swedish Foundation for Strategic Environmental Research, Swedish Research Council for Sustainable Development, Swedish Foundation for International Cooperation in Research and High Education, and the European Union. Pan’s research has been in close collaboration with national and international academic partners as well as industrial partners. Many of the projects have been fully or partly financed by Swedish industries including several industrial PhD projects.