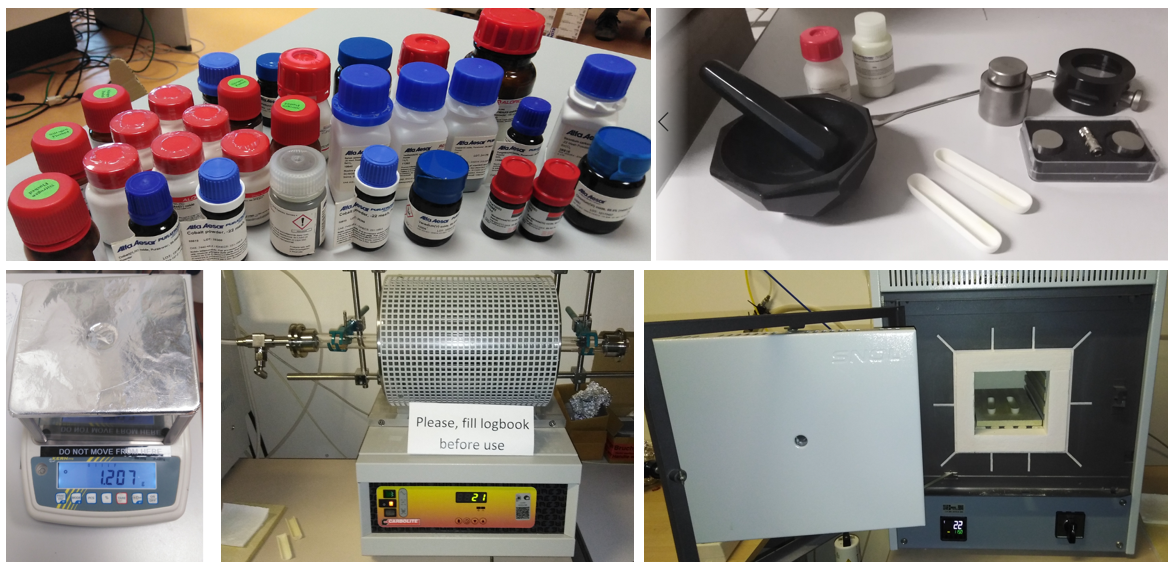

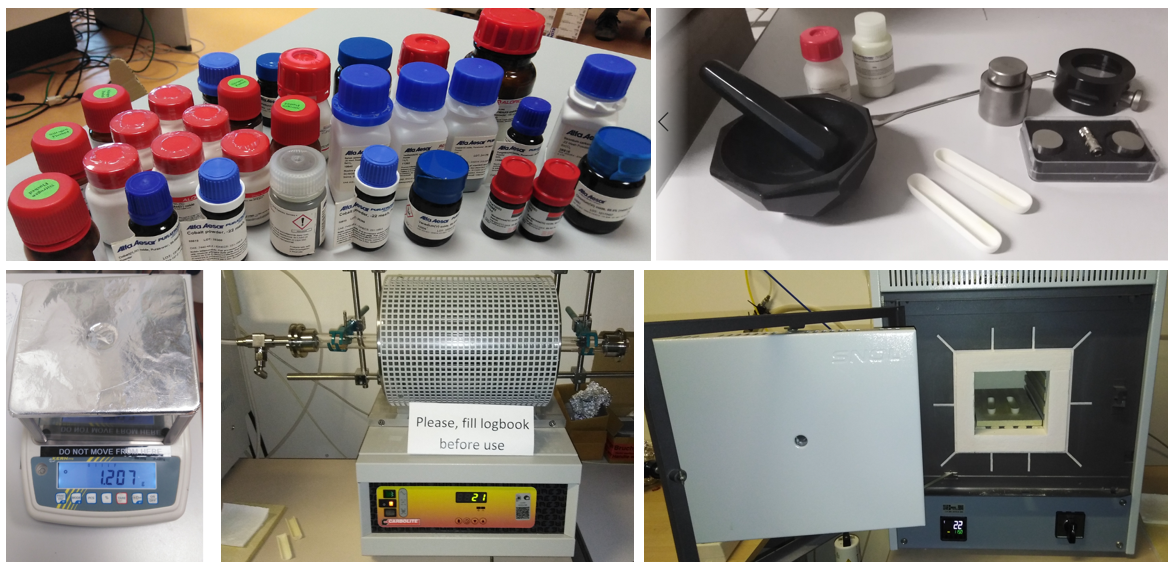

The solid-state reaction route is the most widely used method for the preparation of polycrystalline solids from a mixture of solid starting materials (a). Materials do not usually react at room temperature and it is therefore necessary to heat at high temperatures (often to 1000 to 1500 °C). The reaction depends on environment conditions, structural properties of the reactants, surface area of the solids, their reactivity and the thermodynamic free energy change associated with the reaction. In order to synthesize complex materials, reactants are weighed out in the required amounts (c) and usually mixed by means of agate mortar and pestle (b). Some volatile organic liquid – preferably acetone or alcohol – can be added to the mixture to aid homogenization. If a specific shape is required (e.g. pellets for PLD-targets), evacuable pellet dies can be used (b). However, pelleting of samples is also preferred prior to heating, since it increases the area of contact between the grains.

For the subsequent reaction at high temperatures, it is necessary to choose a suitable container material which is chemically inert to the reactants under the heating conditions used (d,e). Depending on the synthesis temperature crucibles or boats made by noble metals (e.g. platinum, gold) or ceramics (e.g. alumina) are usually suitable. The heating process as well as the control of the background atmosphere depend very much on the form and reactivity of the reactants.

i

@

provided at NFFA-Europe laboratories by:

i

@

provided at NFFA-Europe laboratories by:

Also consider

Structural & Morphology Characterization

SEM Scanning Electron Microscopy

In SEM a beam is scanned over a sample surface while a signal from secondary or back-scattered electrons is recorded. SEM is used to image an area of the sample with nanometric resolution, and also to measure its composition, crystallographic phase distribution and local texture.

Structural & Morphology Characterization

XRD X-Ray Diffraction

XRD provides non-destructive information on the structural order of a material. At large scattering angles XRD permits to identify different crystal phases and to quantify lattice distances and crystalline volume fractions. At low angles of incidence the surface roughness of a single crystal and the thickness of a deposition layer can be obtained.

Electronic & Chemical & Magnetic Characterization

OS Optical spectroscopy

VUV/UV/Vis/NIR spectroscopy is the measurement of the attenuation of a beam of light after it passes through a sample or after reflection from a sample surface. It is useful to characterize absorption, transmission, and reflectivity of a variety of technologically important materials, such as gases, film, pigments, coatings, windows, and filters.

Theory & Simulation

MMMEI Multiscale modeling of materials under extreme irradiation

This techniques offers a multi-scale theoretical framework that allows for the estimation of structural and phase changes when materials are exposed to extreme irradiation conditions generated by various types of electromagnetic sources (e.g. synchrotron sources, pulsed and free-electron lasers).

Electronic & Chemical & Magnetic Characterization

TRLS Time Resolved Luminescence Spectroscopy

P66 beamline, located within PETRA III storage ring, specializes in materials science, enabling precise photoluminescence studies of solids under state-selective excitation via pulsed synchrotron radiation in UHV. It enables recording time-resolved emission and excitation, absorption and reflection spectra across a wide 8-800 K temperature range.