The nanochemistry facility will offer cost-efficient, easily scaled-up and accessible nanocrystals fabrication for the ever demanding field of nanosciences.

The user-oriented approach entails exploitation of new solution-based “bottom-up”, assembly mechanisms that can accomplish structural control at the nanoscale, either by free-energy changes or kinetics. The facility aims to lead to paradigms for assembling functional systems that accomplish desirable properties, either unavailable or prohibitively expensive by using “top-down” approaches (e.g. state-of-the-art lithography techniques applied to semiconductor nanostructures).

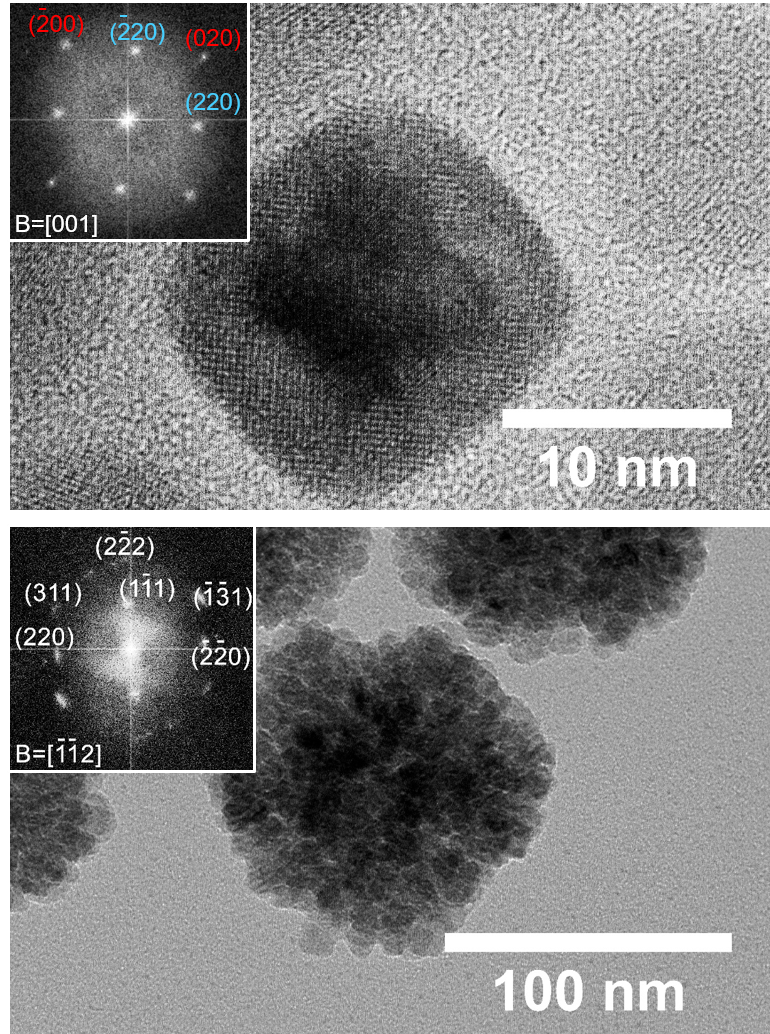

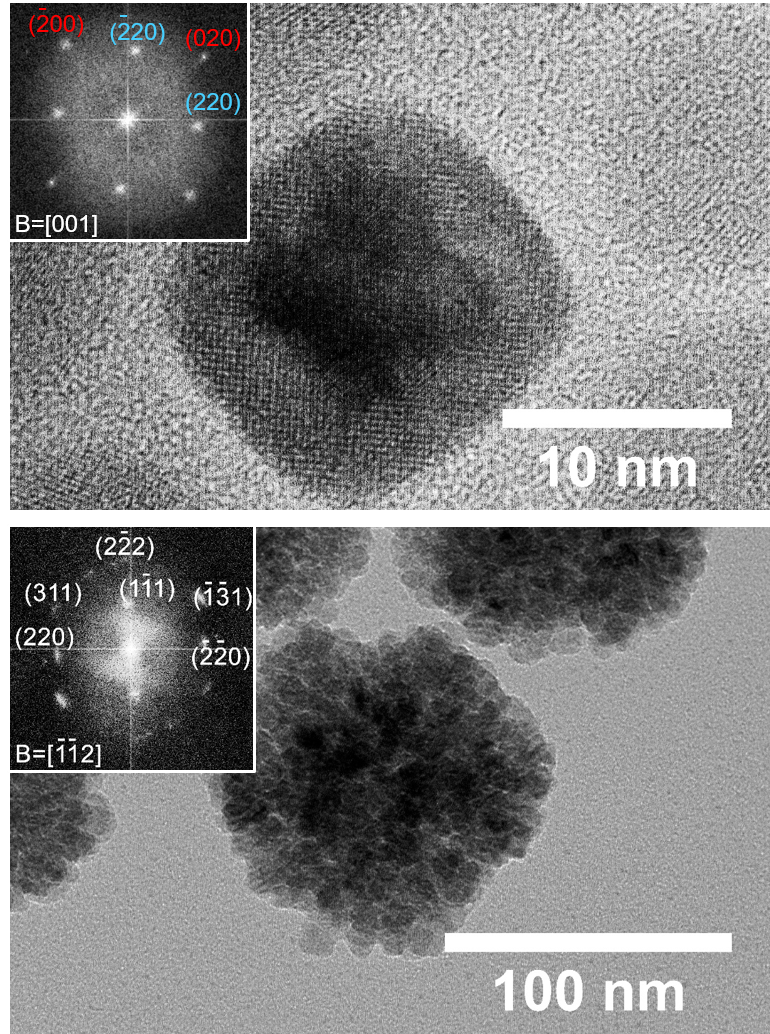

Wet-chemistry techniques for the preparation and characterization of colloidal nanocrystals, with controlled size, shape and composition will be ready available for users in need of nanomaterials with semiconducting, plasmonic, and magnetic natures. However, any material request outside the palette of these systems will be also considered for further development.

The users will be either delivered with the requested nanomaterial or be trained by the laboratory scientists and technicians to undertake synthesis of nanosized colloidal crystals of desired chemical composition (e.g. chalcogenide, noble metal, oxide, halide) and adjustable geometrical characteristics (size and shape). For this, colloidal chemistry techniques will be made available, for nanocrystals’ synthesis and purification, including chemical hoods, equipped with vacuum-inert gas lines (Schlenk type), digital temperature control of the growth conditions, PID-controlled furnaces for post-synthesis treatment and anaerobic glove-boxes for handling and manipulating air-sensitive reagents in the course of each user-based project.

@

provided at NFFA-Europe laboratories by:

@

provided at NFFA-Europe laboratories by:

Also consider

Electronic & Chemical & Magnetic Characterization

OS Optical spectroscopy

VUV/UV/Vis/NIR spectroscopy is the measurement of the attenuation of a beam of light after it passes through a sample or after reflection from a sample surface. It is useful to characterize absorption, transmission, and reflectivity of a variety of technologically important materials, such as gases, film, pigments, coatings, windows, and filters.

Structural & Morphology Characterization

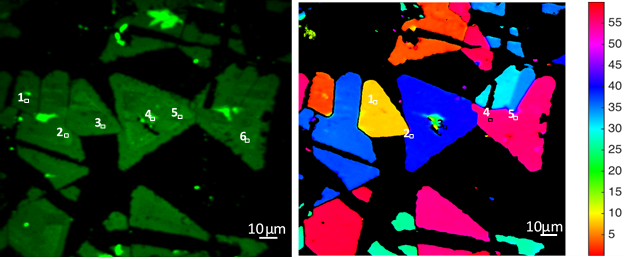

SEM Scanning Electron Microscopy

In SEM a beam is scanned over a sample surface while a signal from secondary or back-scattered electrons is recorded. SEM is used to image an area of the sample with nanometric resolution, and also to measure its composition, crystallographic phase distribution and local texture.

Theory & Simulation

SGSEP Structural and ground-state electronic properties

This technique offers the possibility of simulating structural and electronic properties based on the electronic ground state, including electronic charge analysis, energetics of formation, structural and vibrational properties; IR, Raman, EPR, NMR, core-level XAS & XPS, STM & AFM.

Nano to Micro/Macro

LSIVP Laser surface and in-volume Patterning

Laser patterning is a technique for the controlled patterning of materials at micro- and nano-scales. It offers the ability to directly write patterns on the surface and complex 3D channels into the bulk of solid materials, also biomaterials. Applications can range from microfluidic systems and sensors to tissue engineering scaffolds.

Structural & Morphology Characterization

NLM Nonlinear microscopy

NLM takes advantage of tightly focused ultra-short laser pulses (fs) to excite non-linear optical phenomena like Second Harmonic Generation, Third Harmonic Generation, Two-Photon and Three-photon excited Fluorescence. Along with laser raster-scanning of the sample, non-linear imaging microscopy of large areas is accomplished within seconds.