Modelling and Machine Learning

For laser-processed surfaces

This platform offers to authenticated users two VA services:

Materials Modelling: damage threshold evaluation

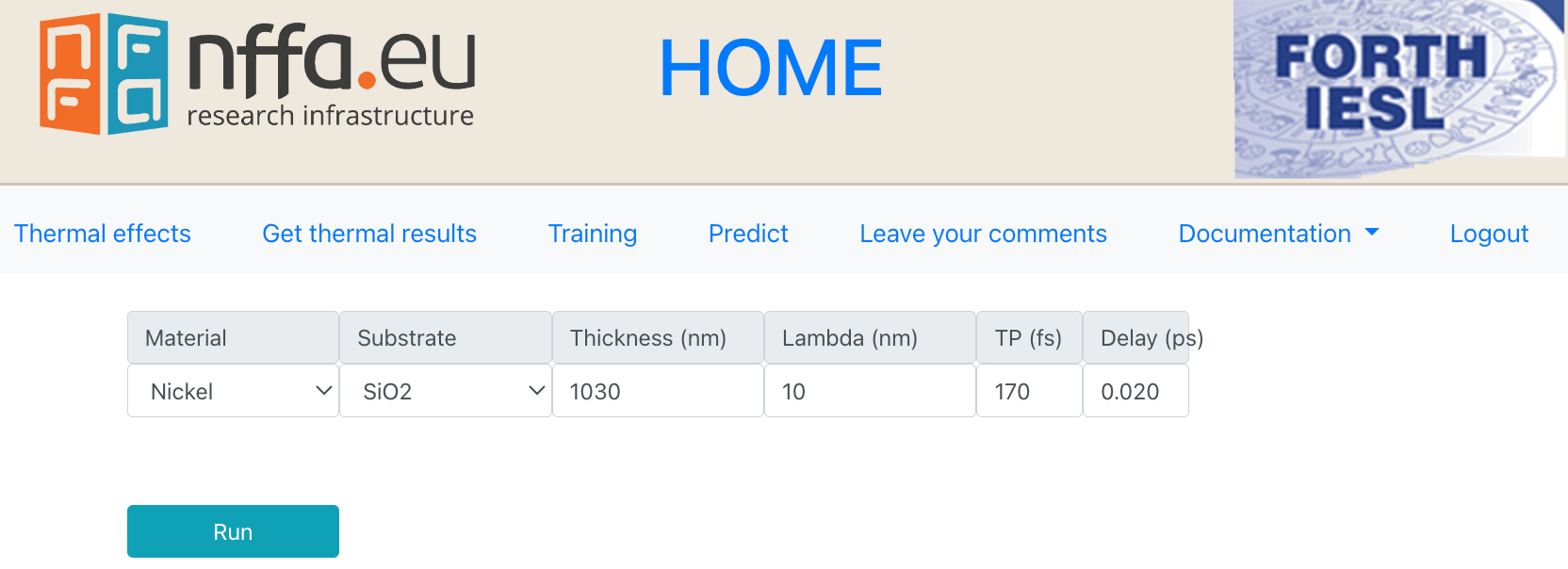

The damage threshold evaluation offers an interface to perform in a user-friendly way the evaluation of the impact of various parameters such as the photon energies, the pulse duration, the pulse separation (in case of double pulse experiments) and the material thickness on the damage threshold for various metals (Au, Ag, Cu, Al, Ni, Ti, Cr, Stainless Steel); three different substrates (Si, SiO2 and soda lime silica glass) have been considered.

Interface for evaluation of damage threshold

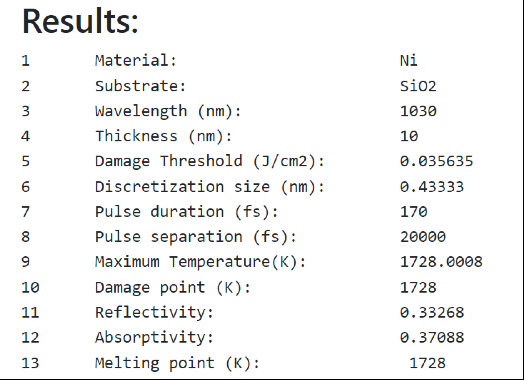

Results are saved in txt format files that contain the prescribed laser conditions and the materials used as well as information of the damage threshold (i.e. minimum fluence to melt the material). The maximum temperature in these conditions and comparison with the melting temperature is used to assess the accuracy of the algorithm. Furthermore, optical parameters (i.e. reflectivity and absorptivity) of the irradiated metals are calculated and their values are included in the txt file. A step-by-step documentation is available, together with the details of the underlying theory that describes the multiscale physical processes that lead to materials damage.

Output of the simulation for the damage threshold evaluation

Machine Learning: Predictive service for nanostructures

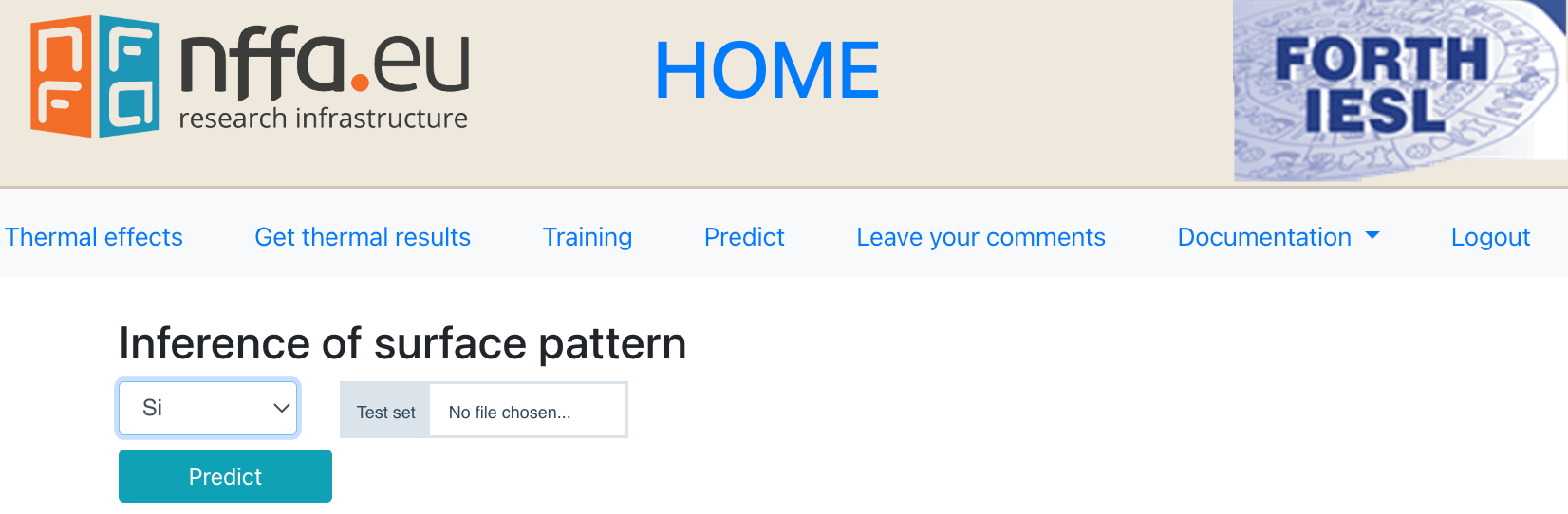

The Predictive Service allows predicting morphological nanostructure of laser-processed surfaces from Machine Learning (ML) models, which have been trained on annotated datasets (Si, Steel 1.7131, Steel 1.7225 and Ti6Al4V).

The predictive model of the service takes as input the natural logarithm of the number of pulses and the fluence, and returns the most probable surface structure. Feature engineering is performed, and new higher-order features are constructed and then fed to the ML models. The software trains several ML models including k-Nearest Neighbours, Gaussian Naive Bayes, Logistic Regression, Support Vector Classifier and Gradient Boosting Classifier.

Interface for the prediction of the most probable surface pattern

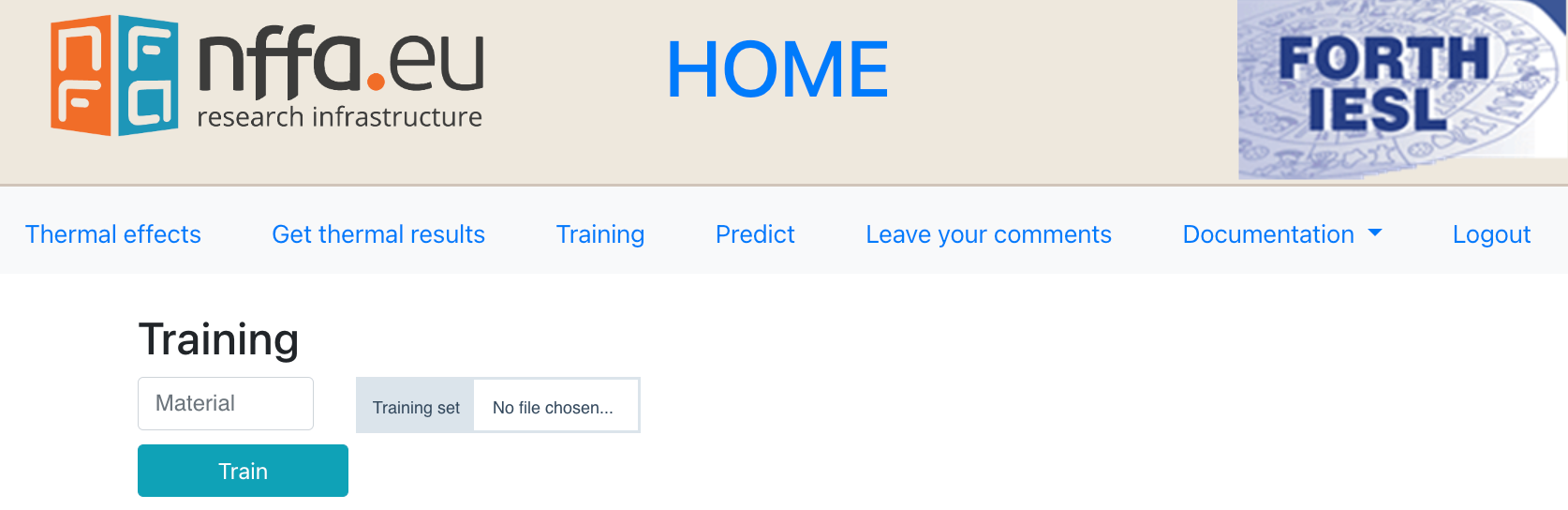

As an alternative, the tool can be used to train the ML models on new materials.

Interface for the training of the ML models on new materials

Contact

George Tsibidis, tsibidis@iesl.forth.gr