Molecular Beam Epitaxy

Growth & Synthesis (Physical depositions of thin films)

Molecular beam epitaxy (MBE) is a growth technique for the deposition of high quality and high purity epitaxial layers on suitable substrates. It is mainly used for the growth of semiconductors, oxides and organic materials.

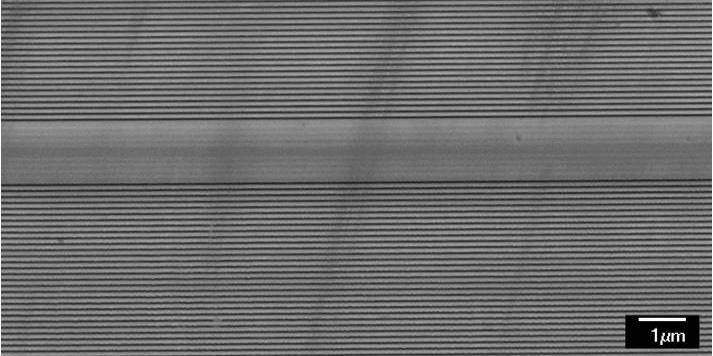

Fully automated MBE systems for the growth of advanced, compound semiconductor heterostructures, composed of compounds based on III-Arsenide, III-nitride, Si, SiC, Ge, C semiconductor nanostructures with sub-nanometer control of the film thicknesses. The MBE system is used to make nanostructures, including quantum dots and nanowires, and epitaxially layered structures and heterostructures, for the fabrication of lasers, photodetectors, light-emitting diodes and other optoelectronic devices. The MBE systems are equipped with a series of in-situ analytical characterization tools for continuous monitoring of the growth process.

Thermally produced atomic or molecular beams of the constituent materials migrate in Ultra High Vacuum (UHV) environment until impinge on a heated substrate where they are incorporated. The growth rate is generally very slow, of the order of one monolayer (ML) per second, allowing a ML control of the deposition.

The UHV environment allows for the use of diagnostic techniques during the growth as the reflection high energy electron diffraction (RHEED) and the integration of the growth system with UHV surface characterization techniques. When combined with the referred ability to perform in-situ high-resolution structural and electronic diagnostics of the films as they are being deposited, MBE provides the ideal scenario for understanding many of the fundamental structural and physical properties of ultrathin inorganic and organic film systems.

In some cases, MBE systems should be prepared not only for in-situ characterization but for in operando as well, in order to study the dynamics of growth. This should lead to the design of compact, element or material specific and flexible systems. In operando studies are particularly interesting for understanding catalytic processes.